Brandoni valves - robotic island and horizontal Machining Centers

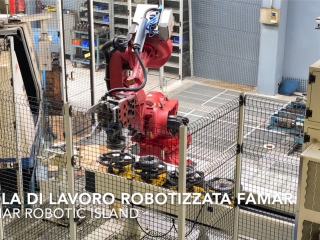

Famar robotic island

It includes a machine body with two integrated turning units, which allows the piece transfer and overturning between the spindles integrated in the machine. This allows us to save time and reduce size of the island area.

The casting is loaded onto the conveyor belt by one of our machinist; the robot picks it up from the belt and places it on a special slide, then it takes the piece machined on one side before leave it again for the second machining; finally it takes the piece machined on both sides and places it on the conveyor belt for the unloading performed by the operator. The piece is now ready for painting.

Mazak HCN 4000 machining center

It is a double pallet horizontal machining center: the machinist loads/unloads the piece on the first pallet while another piece is being processed on the second pallet.

The body of the ECO3T series, threaded end DN50 backflow preventer, is being worked on.

The raw casting is loaded and after machining it is ready for the assembling

Mazak HCN 5000 machining center

It is a double pallet horizontal machining center: the machinist loads/unloads the piece on the first pallet while another piece is being processed on the second pallet.

The body of the EKOFLUX.S series, flanges DN65 static balancing, is being worked on.

The raw casting is loaded and after machining it is ready for the assembling.